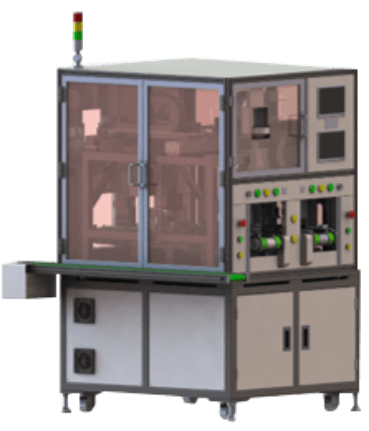

automatic assembly and disassembly clamp special equipment

1. The line equipment adopts modular design, which can realize the automation of the entire process such as product positioning, welding, assembly, disassembly, and re inspection.

2. Multiple types of small items are automatically loaded;

3. Automatic scanning of codes;

4. CCD precise positioning;

5. Integrate with MES to upload real-time production capacity, fail information, location, etc. of workstations.

video display

equipment features

1. Functional modular design, fast integration and wiring

2. Standardized design, quick wire change in 0.5 hours

3. Platform based control software, one click switch for changeover, easy to adjust configuration and upgrade

production process

Loading → Clamping → Welding 1 → Welding 2 → Welding 3 → Welding 4 → Dismantling → ...→ Material cutting

product parameters

| serial number | project | specifications |

|---|---|---|

| 1 | Equipment size | 7000 mm*6500 mm*2000 mm |

| 2 | UPH | ≧320 PCS |

| 3 | CT | ≦11S |

| 4 | Production yield | ≧99.6% |

| 5 | Equipment failure rate | ≦3% |

| 6 | Repeatability | ±0.03 mm |

document materials

recommended products

Contact us for exclusive services

Contact Us