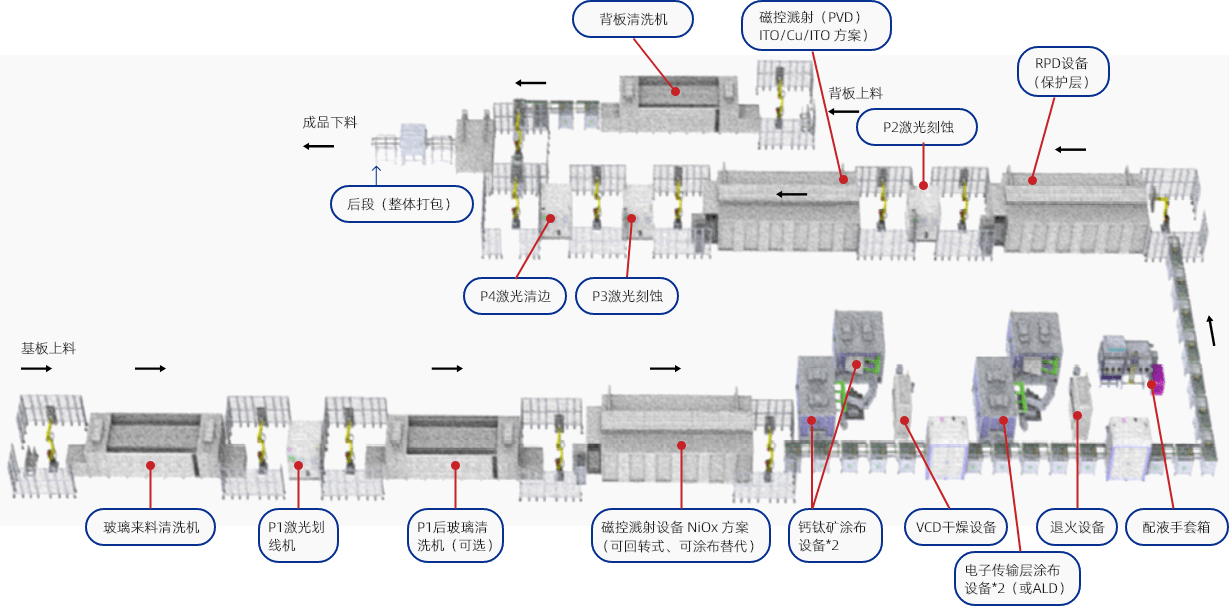

Line description:

1. This layout mainly reflects the process flow of 1200mm (length) * 600mm (width) photovoltaic glass and the interrelationships between equipment. The detailed layout needs to be planned according to the actual site and equipment of the customer;

2. This plan does not currently reflect the equipment required for factory affairs, such as pure water system, air compressor, dryer, nitrogen generator, exhaust, wastewater treatment, power distribution system, cooling tower, etc. This part will be planned after the layout of the factory area is determined;

3. The plan is designed with an annual production capacity of 40MW, with a conversion efficiency of 18% (single piece power of 180 * 0.72=129.6W), an OEE of 85%, and an annual production capacity of 300 days. The daily production capacity is 1286pcs/day, and the single piece glass CT is 72S/pcs;

4. Currently, the planning between various machines is for robots to load and unload materials, and the actual production can be achieved through the combination of human-machine and semi-automatic production according to the customer's actual situation.

| NO | Equipment | Amount | Notes |

|---|---|---|---|

| 1 | Glove box (liquid preparation) | 2 | Dual station |

| 2 | Fully automatic glass cleaning machine | 3 | |

| 3 | UV activation machine (optional) | 1 | |

| 4 | P1, P2, P3 laser marking machine, P4 laser edge cleaning mac | 4 | 3 etching machines, 1 edge cleaning machine |

| 5 | NiOx scheme for magnetron sputtering (PVD) equipment | 1 | Can be coated and replaced |

| 6 | Perovskite coating equipment | 4 | |

| 7 | VCD drying equipment | 2 | |

| 8 | Annealing equipment | 1 | |

| 9 | RPD device | 1 | |

| 10 | Magnetron Sputtering (PVD) Equipment | 1 | |

| 11 | Glass handling robot | 2 | horizontal arms and 4 degrees of freedom |

| 12 | Rear section (lamination, packaging) | 1 | overall packaging |

| 13 | KUKA Six Axis Robot | 9 |

A solution with leading technology and mature applications covering the production of lithium batteries in the front, middle, and rear stages